Markets Served by CCS

CCS towers are renowned for design flexibility, quality and performance.

CCS towers are renowned for design flexibility, quality and performance.

We're the performance and long-term value option for an HVAC project, for both new construction and replacement of an existing tower. CCS towers are energy-efficient, with system configuration and materials selected specifically for your project to maximize efficiency. As a result we can often provide increased capacity, even in the same footprint as your old tower, without doing anything “special”, or adding lead time to the project.

A stronger, longer-lasting, quieter tower.

You'll get a high-quality FRP tower that requires less maintenance and will stay better-looking longer than other FRP towers, with improved resistance to chemicals or fading. Our exclusive open tower structure is stronger and lasts longer than other towers, and makes them easier and safer to maintain. Options available for reduced sound levels and reduced drift can allow closer placement to occupied areas, parking lots and other traffic areas. We can also provide concrete or concrete/FRP hybrid construction to match architectural requirements.

The best for energy-efficiency.

An important consideration for HVAC applications is the ever-changing load on a building with varying occupancy. CCS Counterflow towers utilize our Multi-Flo™ distribution system that allows the number, location and capacity of spray nozzles to be optimized to match tower dimensions and performance requirements. With Multi-Flo, turndown capabilities can be as low as 30-50% of total capacity for efficient tower operation through a wider range of load conditions.

For more details about CCS cooling towers for commercial HVAC, contact your local CCS representative.

CCS Cooling Towers for Industrial applications.

CCS Cooling Towers for Industrial applications.

What makes a cooling tower the better choice for industrial applications? Sometimes, it can be the ability to fit in a physically restricted area, adjacent to or even on top of existing structures. It can be to deliver more capacity within a certain footprint, or to be equipped with features like FM approval on our Phoenix towers without the high cost of sprinkler systems, to ensure the safest operation in close quarters. Our ThermaFit® software helps design and select the optimal tower design for the application from a range of possibilities. For industrial applications, this saves substantial time in initial design stages, matching size and performance requirements to the physical space without being restricted by "standard product" limitations.

Shorter design time, faster installation.

Our software system also automates design and bill of materials creation, enabling faster delivery time of materials to site. With larger columns and spacing, our structure requires 75-85% fewer columns, connections and hardware pieces, reducing installation hours needed. Our pre-packaged/marked components and standardized hardware eliminate guesswork and lower risk by reducing overall time on site.

The choice for Industrial energy-efficiency.

An important consideration for Industrial applications is the ability to economically adjust for load variations in the production cycle. CCS Counterflow towers utilize our Multi-Flo™ distribution system that allows the number, location and capacity of spray nozzles to be optimized to match performance requirements. With Multi-Flo, turndown capabilities can be as low as 30-50% of total capacity for efficient tower operation through a wider range of load conditions. CCS Crossflow tower designs can also use our sparger distribution system, allowing significant turndown capabilities with improved distribution performance over standard single-outlet designs.

For more detailed information about CCS cooling towers for the industrial market, contact your local CCS representative.

CCS cooling towers fit the Process Control market.

CCS cooling towers fit the Process Control market.

While the majority of this market can take full advantage of CCS' standard construction features like our superior FRP formulations and stainless steel components, the flexibility of our tower structure and our design capabilities also lend themselves well to specialized applications supporting process control. Some applications may require unique finish treatments, while others may involve unique integration with other mechanical systems. We are experienced in providing variations on our towers to support specialized processes, from oil and gas facilities and plastics manufacturing to chip processing plants.

A stronger finish for process protection.

CCS' use of proprietary structural components gives us the ability to address a range of application challenges, including standard resistance to many chemical substances and optional finishes for resistance to more caustic chemicals. We select the resin system depending on circulating water chemical composition, either polyester or vinyl. We DO NOT use filler in our structural FRP. CCS also incorporates the heaviest UV protective outer layer in the industry.

Especially important in process markets, our standard practice in fabrication is to seal all saw cuts or penetrations of our FRP structural components with base resin as added protection against moisture or chemical migration. Most of our competitors do not perform this secondary operation in their fabrication.

Reduced operating and maintenance costs.

Because our towers can be built to the exact footprint available, we are able to utilize other variables such as the optimal fill, distribution system, fan horsepower and pump sizes to increase efficiency and reduce operating costs. The open-frame design of our towers allows easy access to both the tower structure and the basin, making it faster, safer and less costly to clean, inspect and service the tower.

For more detailed information about CCS cooling towers for the process market, contact your local CCS representative.

Cooling towers for power plants.

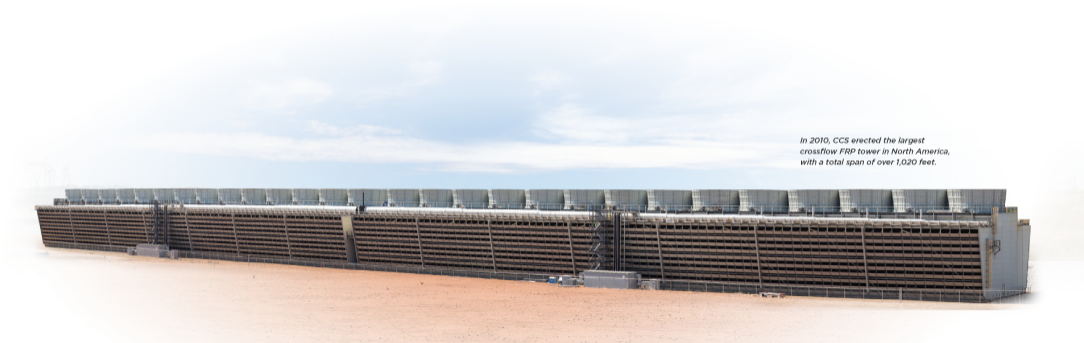

We've designed and erected some of the largest power plant cooling towers in the world, including North America's largest induced-draft crossflow FRP tower. The Titan is engineered to withstand seismic and wind conditions that can be encountered in large installations, using our 6x6-inch "power columns" with spans up to 14 feet for easier service and faster construction. FRP components use our heavier finish coating for a longer service life with greater UV protection and chemical resistance. A patented feature of CCS crossflow towers, including the Titan, is our sparger distribution system. Using a specially-designed piping network to introduce hot water uniformly across the basin (instead of a single entry point), better performance is achieved, especially at reduced flow conditions.

The CCS Titan is engineered for a minimum structural life of 50 years.

Solutions to your unique challenges.

For any power project there can be multiple tower designs that can meet performance requirements. When both long-term performance and lifecycle cost are paramount, it's essential to make the best design decision without being held back by "standard" product limitations. Determining which design is most efficient or presents the best overall lifecycle cost is a challenge we solve on a daily basis. Our technical services group have engineered the Titan specifically for larger process and power generation applications, and will help you determine the exact tower configuration that is optimal for your project.

Accountable partner you can trust.

CCS' experience in power generation towers shows in more than our tower performance - it shows in our history of delivering finished towers on schedule, with an outstanding safety record. This takes exceptional project planning and management skills, as well as a design that contributes to safety. Our tower structure uses 75-85% fewer but stronger components and connections with standardized hardware. This yields a faster and safer construction cycle, as workers can use scissor lifts instead of ladders, need fewer tools, and can tie off anywhere in the structure. Our lean assembly processes include pre-packaged and marked components to improve jobsite organization and reduce time on site.

Our designers, management and installation teams are all committed to creating a safe, zero-accident project.

For more detailed information about CCS cooling towers for the power generation market, contact your local CCS representative.